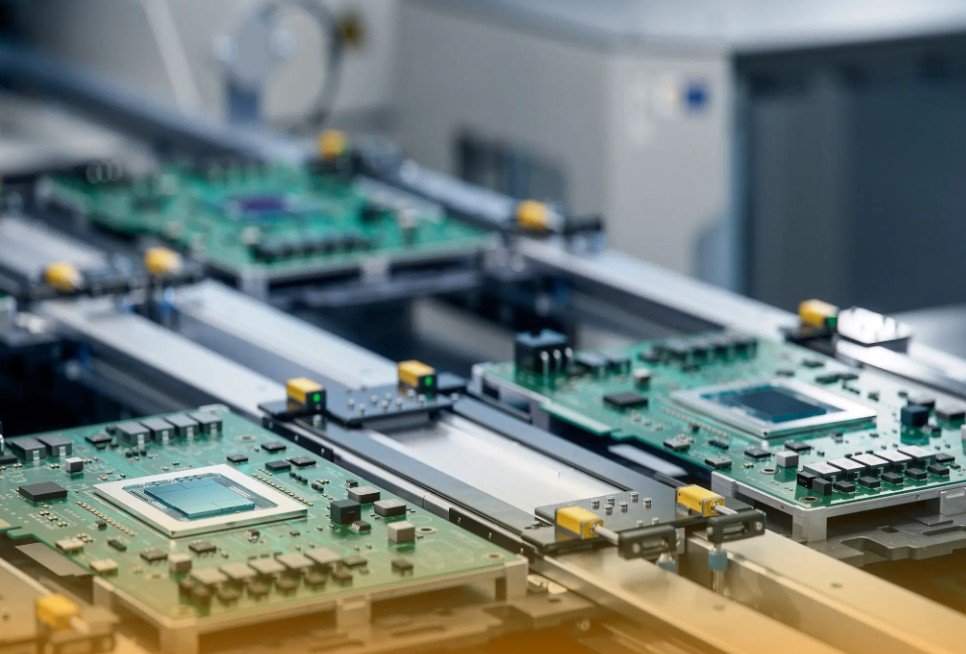

China-based FR4PCB.TECH says it is expanding PCB assembly OEM collaboration for global brands as electronics companies increasingly demand integrated design, manufacturability insight, and scalable production under unified quality controls. The Shenzhen provider positions itself as a partner for brands seeking PCB fabrication, sourcing, assembly, testing, and logistics support inside a single managed workflow.

Manufacturers and electronics brands are moving away from transactional production relationships toward deeper technical coordination, as complexity, reliability demands, and supply-chain pressures reshape procurement expectations.

Integrated OEM Support Becomes More Important for Electronics Brands

OEM buyers in sectors such as automotive, telecommunications, industrial controls, and IoT are asking suppliers to shorten development cycles and provide engineering participation during design stages. Instead of final blueprints arriving fully locked, suppliers are being asked for feedback on layout choices, BOM refinement, component sourcing feasibility, and tooling implications.

One sentence: Manufacturing now begins earlier in the design process.

This is partly due to rising product density, miniaturization, and increased traceability expectations. Using a collaborative OEM partner reduces redesign risk, avoids late-stage manufacturability problems, and strengthens supply continuity throughout a product’s lifecycle.

-

Integrated PCB partners often support design-for-manufacturing checks, material validation, prototype builds, and higher-volume runs under similar process specifications.

The bullet point explains why many global companies want unified oversight rather than fragmented sourcing.

A one-sentence paragraph: Brands want consistency and fewer late surprises.

FR4PCB.TECH Describes Its OEM and ODM Capabilities

FR4PCB.TECH reports that its operating model covers PCB fabrication, BOM analysis, circuit layout support, component sourcing, SMT and through-hole assembly, electrical and functional testing, and export logistics. The company says consolidating these steps reduces handoffs and improves traceability for both prototype and volume manufacturing.

One sentence: Accountability stays in one production channel.

The team says it participates in layout tuning, manufacturability planning, and sourcing selections to support stable cost structures and long-term availability. According to company information, this approach helps avoid duplicated vendor coordination, unclear production responsibility, or disjointed quality systems across multiple suppliers.

Here is a compact table illustrating differences between integrated OEM partnerships and traditional production-only models:

| Category | Traditional Supplier | Integrated OEM Partner |

|---|---|---|

| Design review | Limited or none | Supported throughout development |

| Production scope | Fabrication/assembly only | Fabrication, sourcing, testing, logistics |

| BOM feedback | Customer-managed | Joint planning for availability and cost |

| Prototype scaling | Often separate vendors | Same controls from prototype to volume |

| Accountability | Distributed | Centralized under single workflow |

This table highlights why OEM buyers increasingly prefer end-to-end coordination.

A short one-sentence paragraph: Fewer vendors means fewer moving parts.

Industry Shifts Driving OEM Model Adoption

Electronics brands face shorter product cycles, tighter compliance requirements, and more unpredictable supply conditions. Recent geopolitical changes and freight disruptions have made procurement teams favor partners that can scale production in multiple directions — from low-volume engineering runs to higher-volume releases — without changing process validation or documentation.

One sentence: Stability has become a strategic advantage.

FR4PCB.TECH says this shift reflects a long-term transformation in manufacturing expectations, where suppliers are judged by their engineering capacity, not just their unit pricing. OEM buyers are prioritizing reliability, revision control, and traceable production records while retaining flexibility across changing volumes.

Some procurement teams now evaluate suppliers based on collaboration depth and technical responsiveness rather than only quoting and assembly cost. For many PCB-based systems, early manufacturability checks reduce delays later in certification, integration, or safety documentation.

A short one-sentence paragraph: Development friction is expensive.

How Global Electronics Brands Are Adjusting Supplier Selection

According to FR4PCB.TECH, more international OEMs are requiring unified supplier models that integrate design refinement, materials sourcing, and test assurance under the same quality framework that applies to scaled production. The company states that this reduces the likelihood of redesign loops caused by incompatible component sourcing, layout changes, or factory-level constraints.

One sentence: Engineering time is often more costly than factory time.

The partner model typically involves:

-

Layout assessment and manufacturability input

-

BOM review for sourcing risk and lifecycle planning

-

Prototyping under the same controls used for scaled builds

-

SMT and through-hole assembly with consistent documentation

-

Testing and inspection before shipment

-

Export packaging and logistics coordination

These combined steps, according to the company, allow OEMs to maintain a continuous technical relationship rather than transactional ordering.

Short paragraph: Brands want fewer blind spots during product release.